Process Optimization

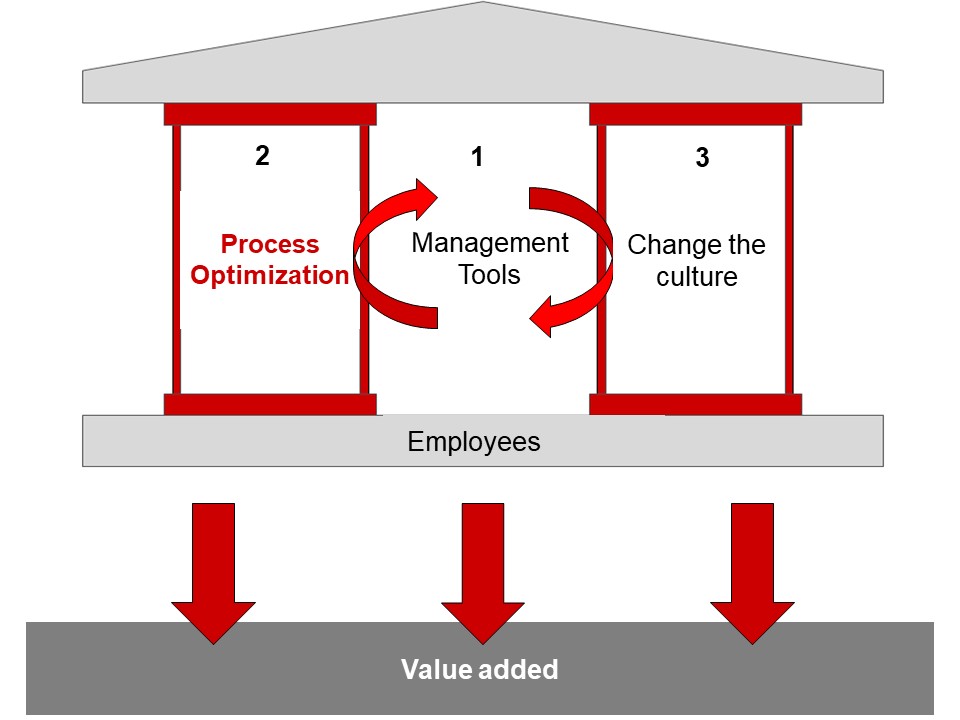

1. Establish process optimization as part of the corporate culture

Companies that want to optimize their processes and thus achieve long-term success should ensure their readiness for process-oriented management, first and foremost at the management level. Because here too, as with other topics that affect the strategic direction of the company, everyone must pull together. Otherwise, even at the management level, resistances are preprogrammed that will permeate all levels of the company and thus sooner or later fail the project.

2. Set pilot

As long as nobody feels responsible, the process will fall asleep like Sleeping Beauty awaiting the prince's kiss. Until then everything is dusty and rusty. It makes sense, therefore, as early as possible to determine process managers (pilot and co-pilot). For smaller companies this could be the respective department manager.

For larger companies, it pays to hire a Chief Restructuring Officer (CRO) to oversee corporate processes, work closely with management, and report directly to senior management.

3. Identify and prioritize core processes

If the responsibilities are clearly distributed and there is agreement on process-oriented company management, the process owners, with the support of the employees of the respective departments, should draw up a list of the processes and divide them into core processes and ancillary processes. A core process, for example, is a process that is carried out by several employees on a regular basis (usually daily). Processes that are rather irregular or rarely executed are ancillary processes. Depending on the company, other definitions can also be found.

Once the core processes have been identified, it is important to prioritize them for further action. It has proven itself to start with the process that is most frequently performed. If the topic is completely new to the business, it's a good idea to choose a process that will not be impacted by changes in IT structure, major conversions, or other cost factors to achieve success and experience as quickly as possible collect (low hanging fruits).

4. Record

Now the real work begins. The process must be recorded. The easiest and most effective way is for the person responsible for the process to accompany the employees, to work on the respective process and to write down the individual process steps in order to later visualize them using suitable methods. It is also conceivable to make video recordings in order to enable the evaluation outside of the live operation or - if several employees work on the process - to create a benchmarking.

5. Visualize

Choose a suitable method to document the process. From post-it to power-point to software-based flowcharts, anything is possible, but digital versions make the most sense over the long term. A global standard, which is also gaining importance in Germany, is the modeling language Business Process Modeling Notation (BPMN).

6. Measuring

If the process is documented, the individual sub-steps are measured using suitable methods (for example a stopwatch). Travel times, lay times, waiting times and working hours must be included, if possible separated according to the type of processing time. This computes the total time of the process. In the end, the results can also be used to derive costs for the individual process steps and the overall process that can be used for optimization and control.

7. Define the goal

Once the process has been documented and the total time measured, a goal for process optimization should be set. The ultimate goal is usually to increase customer satisfaction (internal and external customers). Various sub-goals can be set for this purpose, such as the reduction of process costs, by optimizing pass, lay and / or waiting times or the reduction of customer contacts per process. Important: The goal should be realistic and measurable.

8. Optimize

Already during the start of the process, there are often suggestions for optimization on the part of the employees or also by the employee who carries out the documentation. These should be noted in order to check their meaningfulness and practicability in the optimization phase. The design of the optimization phase depends on the abilities of the responsible person. If he has a certain routine and enough insight into the process, he can work out an optimized process flow on his own.

However, it is better to work out a proposal with a small team of process owners and process users in a one-hour or several-hour workshop and to check its feasibility. Now the process with the improvements / changes should be re-documented and checked with the manager of the responsible department for its feasibility. Once a general agreement has been reached, the proposal can be implemented.

9. Exercise

The training is a sensitive step that should be carried out with tact. Because now it's about changing and harmonizing well-rehearsed processes. Perhaps the process manager has already succeeded in identifying the driving forces of the respective process in the previous steps - ie the employees who are ready for a change and can also transfer their enthusiasm to doubters. This opportunity should be used to start training for this person or group.

Training is a major step in optimization. On the one hand, this is the opportunity to standardize the new process for all employees, and on the other hand, experience has shown that there is feedback during the training that can be used further to bring about the final touches.

10. Check

The process is optimized, the team is trained and the goals are defined - now we're done, you might think. This is a common mistake that many would expect from project management and should not happen in process optimization. The process of the new process must be put through its paces. There are several reasons for that:

a) Measurable success can be better communicated than gut feelings. There will always be doubters who do not want to implement process optimization or understand meaning. Changes often trigger fears. Control the success of the optimization, you have valid arguments in hand, to bring even doubters on the boat.

b) The first step in process optimization is the establishment as part of the corporate culture. Analyze their successes regularly, this is the best motivation to tackle further processes. In the long term, they help to ensure that process optimization does not have to be learned anymore.

c) Not every optimization is an optimization. If the changes are negative and the process takes longer or delayed follow-up processes, you can read off the numbers and take countermeasures. You should take the analysis seriously.

Current information, workshops, zoom meetings and the latest training courses can be found in my LEARNWORLD.