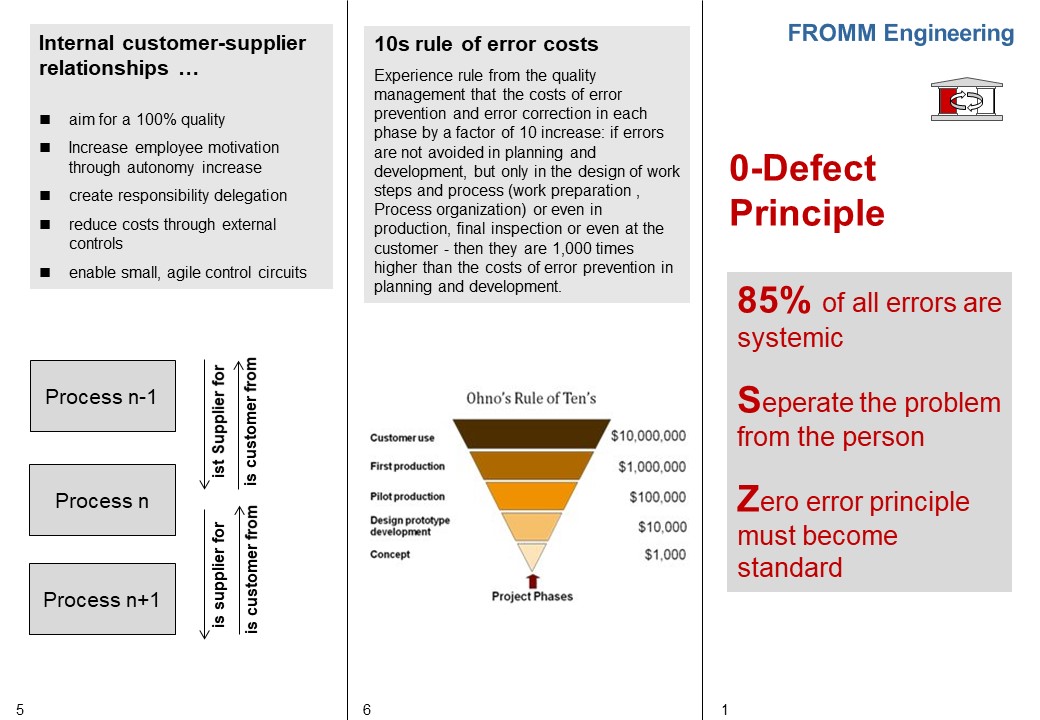

0-Defect Principle

The zero-defect principle is an aspiration of all parties to reduce the error rate to zero. This includes all measures and precautions that make processes and instructions safe, comprehensible and controllable.

One of the principles is Poka Yoke.

It comes from Japanese and means "avoid accidental wrongdoing" or "foolproof".

It describes a system consisting of several components, which contains technical measures or devices for the immediate detection and avoidance of errors.

Zero-defect production means ...

- There is no acceptable level of error

- Every mistake is tracked and the causes fought

- The achievement of quality has absolute priority before reaching the quantity

Every employee is entitled and obliged to stop the production in the event of an irregularity (material, machine or product)!

Current information, workshops, zoom meetings and the latest training courses can be found in my LEARNWORLD.